Formulation & Enabling Technology For Improved And Accelerated Strategy From Lead Optimization To Clinical Trials

Bridging the Drug Substance/Drug Product Interface

While bioactive compounds are frequently derived from natural and synthesis sources, few of these compounds become drug substances, and even fewer are developed into drug products. Among the many barriers separating Drug Substance from Drug Product, the inherent, undesirable physicochemical properties of many drug candidates rank as one of the industry’s most challenging obstacles. Successfully resolving this issue to bridge the gap between Drug Substance and Drug Product is one of J-Star Research’s specialties and greatest strengths.

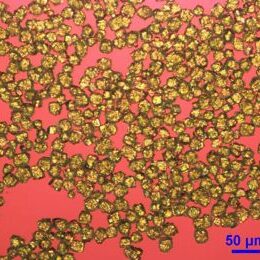

With the ability to develop both Drug Substance and Drug product under the same umbrella, our team enjoys a synergism absent in most CROs. We enable the development of robust drug product processes to meet Quality Target Product Profile (QTPP) requirements by seamlessly combining expert drug substance crystal design with the rapid and simultaneous optimization of desirable drug product intermediate properties, including improved powder flowability, optimized shape and size, increased bulk density, enhanced solubility and dissolution rate, and improved bioavailability.

Normally this kind of work is conducted in the early formulation development stage, but J-Star can leverage its expertise in drug substance crystallization and modification to complete it earlier - even before preclinical study! Our ability to bridge the Drug Substance and Drug Product interface is a major competitive advantage, producing shorter development timelines and improved Drug Product ruggedness.

J-Star’s Drug Product Development division has developed technology platforms able to optimize API powder properties and improve aqueous dissolution as needed. Thus, we can effectively address issues affecting formulation early in Phase I.

This fundamental material knowledge forms the basis of our Quality by Design (QbD) approach to improving Phase II, Phase III, and commercial processes. Our formulation design and process scale-up are also assisted by Physiologically based pharmacokinetic/ biopharmaceutics modeling (PBPK and PBBM) and process unit operation model predictions.

This ability – combined with our dedicated team of specialized Project Managers devoted to responsive customer service – makes us a unique “one stop shop” giving you the best possible experience with the development of your product.